.png?x-oss-process=image/resize,w_100/quality,q_100)

|

Locking force |

A |

4.86±0.45N |

|

B |

/ |

|

|

Durability |

A |

11000 |

|

B |

/ |

|

|

Unlocking force |

A |

/ |

|

B |

M1=4±2N.MM M2=6±4N.MM |

|

|

Locking force |

A |

/ |

|

B |

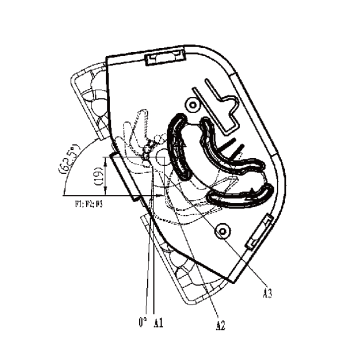

A1=3±3°,A2=25±3°,A3=45±3°, |

|

|

Durability |

A |

/ |

|

B |

F1=0.18N,F2=0.23N,F3=20N |

|

1.Neutral salt spray test: After locking in the salt spray test for 48 hours, there is no corrosion except at the rivet joints.

2.In high and low temperature environments, perform 10 cycles of the following procedure with no deformation of plastic parts: a) Ramp up to 90°C, hold for 4 hours; b) Ramp down to 20°C, hold for 0.5 hours; c) Ramp down to -40°C, hold for 1.5 hours; d) Ramp up to 20°C, hold for 0.5 hours.

3.Material restrictions must comply with the End-of-Life Vehicles Directive EU 2000/53/EC.

4.VOC/SVOC requirements:

GMW14444(2014) 4.5.1 VOC ≤ 300; SVOC ≤ 500; Benzene ≤ 1; Toluene ≤ 8; Ethylbenzene ≤ 8; Xylene ≤ 8; Styrene ≤ 8.

.png?x-oss-process=image/resize)

.png)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)